Trust, early market dialogue, and ongoing project development are among the main ingredients in an innovative construction partnership for Port of Aalborg’s quay expansion in Aalborg East. Besides increasing the carrying capacity by over 50 percent, the partnership has so far reduced CO2 emissions by 30 percent with little extra costs.

Per Aarsleff A/S, COWI, and Port of Aalborg are currently pushing the limits of green and functional quality in major construction projects.

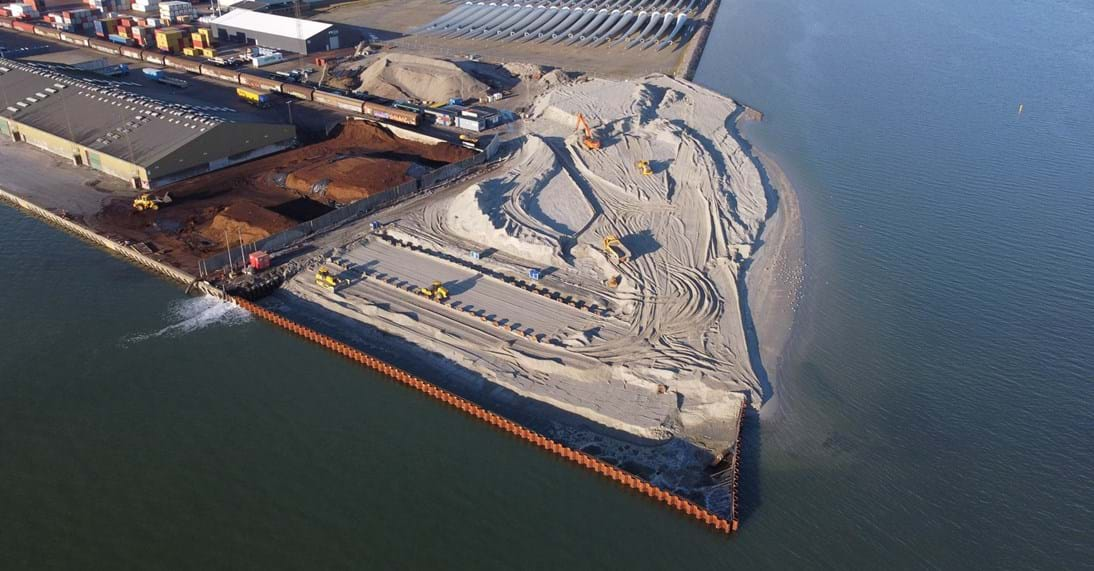

The three partners are working on a 100-meter quay expansion, a new 250-meter rockfill, and a 27,800 sqm new terminal area in the port’s East Harbour in Aalborg. (Read more about the expansion)

In the spring, Port of Aalborg, in close cooperation with COWI, decided to tender the project in form of a partnership model instead of a traditional turnkey contract. This decision has so far reduced the project’s CO2 emission by up to 30 percent.

– While our operation composes a small part of our CO2 records, the situation is different with construction. With this project, we wanted to challenge ourselves and the industry on how far we can go within sustainable construction. The result is a significant reduction of CO2 emissions and a blueprint of our new partnership model that we intend to use for similar projects in the future, says Brian Dalby Rasmussen, Project Manager at Port of Aalborg.

A partnership built on trust

Unlike traditional construction projects, contractors and suppliers are in close cooperation during the early stages of the project, while the consulting engineers continue through most of the construction.

– To raise the bar for sustainable constructions, we have forced ourselves to broaden our perspective beyond the usual, seeking inspiration and ideas from outside our organisation. We thus benefit from advising and utilising experts in design, delivery, and more, allowing us to challenge each other and increase quality throughout the project. This has so far reduced the project’s carbon footprint and increased the quay’s efficiency, says Brian Dalby Rasmussen.

Even though partnerships offer several benefits, construction projects rarely use a model like this, says Casper Holmgaard Jensen, Leading Project Manager at the consulting engineering company, COWI:

– Efficient partnerships are usually based on trust between the involved parties, as they are more open compared to standard tenders that often restraints the contractor. This openness is the model’s strength because it allows the project to continuously create value for all parties.

With the partnership agreement, the budget is also defined in advance. If the parties find savings along the way, they will be reinvested in the project. That is also why the quay’s loading capacity will be 7,5 tons per sqm instead of the initial 5 tons, increasing crane location flexibility.

Perfect conditions for recycling

From 2023, new Danish legislation will limit the level of CO2 that new buildings can emit over a 50-year period.

According to Patrick Justesen, Project Manager at Per Aarsleff A/S, the quay expansion is an opportunity to prepare for the coming legislation. Per Aarsleff A/S is a Danish construction group won the partnership tender before the summer holidays in front of two other contractors.

– This project allows us to develop our company in a sustainable direction that will soon be a legal requirement and already is a competitive parameter. We consider this partnership a framework rather than a straitjacket because it makes us think outside the box and find solutions that can raise functionality and sustainability, Patrick Justesen explains and continues:

– The recycled materials are a good example of this. To avoid issues with the contractor, the developer in a traditional tender usually makes sure the project can include recycled materials before it is written into the tender. This hampers opportunities during the project that could potentially result in a cheaper, greener solution.

The initial CO2 reduction of 30 percent was achieved through greener transport, HVO diesel, and recycling of spuns, bollards, and crushed granite — among other things. The crushed granite is a waste material originating from renovated railway lines in North Jutland.

The construction has already commenced, and the new quay area is expected to be commissioned on 1 June 2022.

For further information please contact:

Weighting in the partnership tender

Three contractors were allowed to formulate an offer for the project. In the assessment, three selected criteria were weighted as follows:

CO2 reducing measures during the quay construction

Aalborg Renewables

Langerak 15

DK-9220 Aalborg Øst